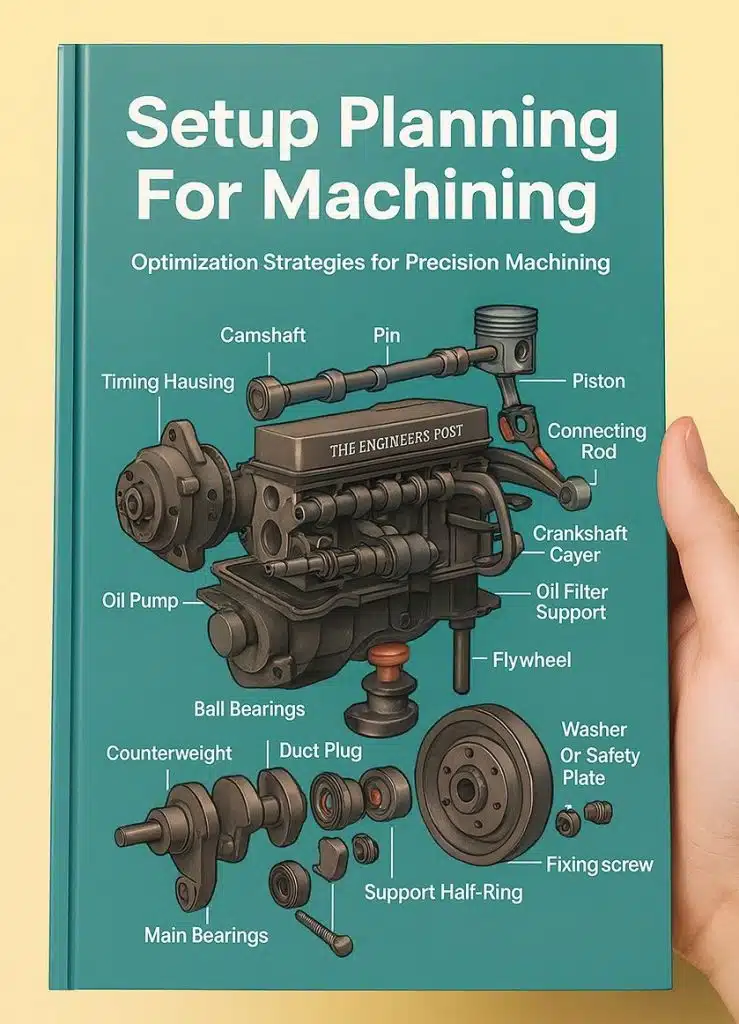

Setup Planning For Machining

Essential Guide: “Setup Planning For Machining” – Optimize Your Manufacturing Process

Unlock the full potential of your machining operations with the comprehensive guide, “Setup Planning For Machining.” This book is an indispensable resource for both manufacturing professionals and researchers seeking to master the crucial link between product design and efficient production. It provides a deep dive into the theoretical framework and practical application of setup planning, a vital component of successful process planning in machining.

What the Book Covers and Why It’s Essential 🛠️

“Setup Planning For Machining” offers a structured, step-by-step methodology for tackling the complex task of defining machining setups. The book delivers immense value by:

- Explaining Significance: It thoroughly introduces the concept and highlights the significance of setup planning within the broader context of process planning, including its external constraints.

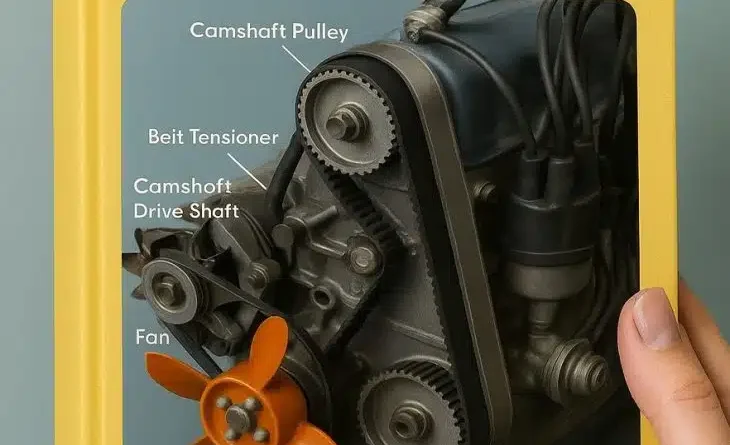

- Outlining Phases: It meticulously details the different phases of setup planning, which typically include:

- Feature Grouping: Organizing features based on criteria like tool approach direction and tolerance relations.

- Setup Formation: Defining the necessary machine setups.

- Datum Selection: Choosing optimal reference points.

- Machining Operation Sequencing and Setup Sequencing: Determining the most efficient order of operations and setups.

- Presenting Methodologies: It covers both traditional and modern approaches to solving setup planning problems, including cutting-edge techniques such as fuzzy logic-based setup planning.

- Providing Practical Insight: It includes detailed examples of applications that offer clear and accessible insights into up-to-date techniques and various setup planning strategies, making theoretical concepts easy to apply.

- Addressing Critical Constraints: The book gives dedicated attention to crucial technical issues like fixturing consideration in setup planning to ensure accuracy and rigidity.

Key Features and Benefits (SEO Focus: Machining, Setup Planning, Process Planning) 💡

This guide stands out as a top-tier resource in manufacturing engineering and CNC process planning due to its key features:

| Feature | Benefit for the Reader |

| Comprehensive Introduction | Establishes a solid foundation in process planning and its constraints. |

| Focus on Modern Techniques | Introduces advanced solutions like Fuzzy Logic for complex problems, reflecting the latest state of research. |

| Practical, Hands-on Examples | Allows for direct application of concepts to real-world machining setups and scenarios. |

| Detailed Phase Breakdown | Offers a clear roadmap for setup formation, datum selection, and operation sequencing. |

| Dual Audience Appeal | Highly beneficial for both industry professionals (engineers, planners) and academic researchers. |

How to Benefit from This Book & Get It for Free! 🎁

Acquiring “Setup Planning For Machining” is vital for anyone aiming to:

- Improve Precision: Learn how to select the correct datums and sequences to ensure tighter tolerances and better part quality.

- Reduce Cost & Time: Master optimal setup sequencing to minimize non-machining time and machine downtime, boosting overall manufacturing efficiency.

- Implement Automation: Understand the principles required for the computer-aided automation of setup planning.

Don’t miss the chance to elevate your expertise! You can obtain this critical resource for free right here on our website, MecTips. Simply click the download link below.

🔗 [GET “Setup Planning For Machining” FREE DOWNLOAD HERE]

Suggested Related Machining Resources 📚

To further enhance your manufacturing knowledge and practical skills, we recommend these similar books available on MecTips:

- CNC Machining and Programming Fundamentals: Essential for practical implementation of your setup plans.

- Advanced Fixture Design: Deepen your understanding of workholding principles vital for complex setups.

- Computer-Aided Process Planning (CAPP): Explore the digital automation of the entire process planning workflow.